Indice

CLIL module on robotics

Foreword

Robotics is a very complex topic; what follows is just an over-simplified introduction.

This page contains many external links that lead to self-explanatory videos, pages from Wikipedia or other reliable sources.

The first part of this module is a quick introduction to industrial robots. The second part is about industrial robot simulation with a software called RoboDK.

Industrial robots

A robot is a machine capable of carrying out a complex series of actions automatically.

An industrial robot is a robot system used for manufacturing. Typical applications include:

- welding

- painting

- assembling and pick and place

- product inspection and testing

These tasks are accomplished with high endurance, speed, and precision.

Most industrial robots are articulated robots, with four or more rotary joints. These robots are often called robotic arms or manipulators. They are powered by electric motors and are computer controlled. To accomplish different tasks different tools - or end-effectors - are used, such as:

- pneumatic or electric grippers

- vacuum grippers

- welders

- paint sprayers

These tools are attached to the robot flange at the end of the robot arm. The robot can move its tool to different positions, along defined paths, to perform a task.

Robot features

Robot features include:

- payload: the maximum weight it can carry on its flange

- reach: how far the tool can go

- working envelope: the region of space that can be reached by the end-effector

- speed

- accuracy and repeatability

- DOF (or Degrees of Freedom): number of independent motions, which is usually the same as the number of axes

Types of robots

There most common types of industrial robots are:

- SCARA robots, which are 4 DOF fast, simple and accurate robots

- delta robots, which are 4 DOF very fast and low-inertia robots

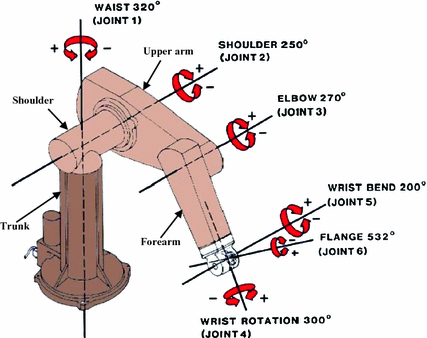

The figure below shows a PUMA-like articulated robot with its six joints.

At the moment a new type of robot is becoming more and more popular: collaborative robots or cobots. These robots are meant to work side by side with people without barriers or fences. This is possible because they're smaller, lighter and slower than industrial robots. Moreover many safety measures are in place to avoid being hurt, including sensors to detect a possible contact and stop immediately in case of collision. This kind of robots are also very easy to use and can be programmed manually moving the robot arm and teaching target positions at the touch of a button.

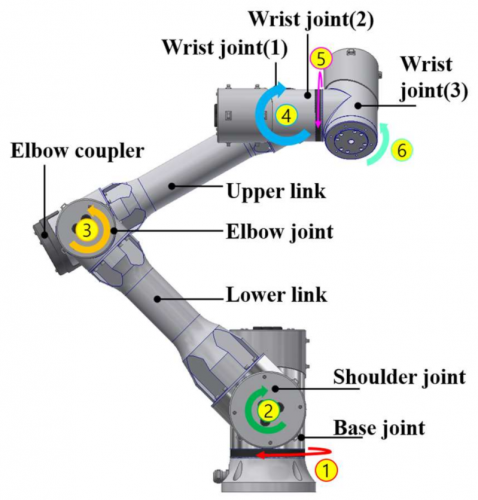

The figure below shows a typical collaborative robot with its six joints.

Robot movements

Robot movements can be defined in two ways:

- joint axis jog, specifying each joint axis position in degrees

- defining target positions, specifying the end-effector Cartesian position (x,y,z coordinates and axes orientation) and a preferred path to get there (either linear or circular)

The latter is much more convenient and is by far the most used, but requires inverse kinematic calculations to be performed by the robot controller, in order to find out joints position and velocity to get to the target. When doing so it should be considered that:

- each target can be reached with more than one configuration (joint and link positions)

- some configurations or some paths must be avoided because of singularities; these are configurations where one or more joints are blocked, velocity increases rapidly and inverse kinematic calculations can fail (see this video or this one)

Robot programming

Every robot comes with a controller, which has the double purpose of powering the robot (like a driver) and doing calculations and interfacing it with other devices (like a computer). Most robots come with a particular device, attached to its controller, called teach pendant. This is an handheld touchscreen device used to directly control the robot, moving or jogging its axes, and to program it with a simple interface.

The teach pendant allows to program the robot by moving its end-effector to the desired positions, saving target points to be reached, specifying paths to follow and actions to be performed by the tool. Once finished the robot will repeat these steps autonomously. Such method, called on-line programming, requires the presence of the robot and its operator in the production environment. Conversely off-line programming happens elsewhere on a PC, and makes use of a more powerful Integrated Development Environment which can often simulate the robot and its environment. This allows for testing multiple scenarios before setting up the robotic cell and using more complex tools or languages when required.

Future plans

Our school will use PNRR funds to buy two collaborative robots: an ABB YuMi IRB 14050 and a Yaskawa HC10. These are the best fit for a school lab environment because:

- they are lightweight, small and can be easily moved around

- they are low power and can be operated from a standard AC outlet

- they are safe to use next to people and need no barriers or fences

- while being easy to use they can also be programmed with the same software applications used for more powerful industrial robots